Crusher Plant 200-250 T/H

Main parts:

- Jaw crusher

- Hydra-con crusher

- Vibrating Screen(3)

- Horizontal Feeder

- Conveyor Belt(230)

- Power Control & cable

PROJECTS

What is included

Jaw Crusher 110*95

- High power and capacity in crushing

- Abrasion Parts made of Mn Steel

- Tenacious Structure &high resistance

- High &Equal Output

- Pretty Designing &Confident Operation

- Quick &easy replacements of Spare Parts

- Less Abrasion &more resistance compare to the similar Crushers

| Specifications: |

| Model : 110 *95 |

| Dimension(m) : L 3.15 * W 2.61 * H 3.22 |

| Weight(kg) : 36,000 |

| Capacity (t/h): 200 |

| Feed opening(mm): 1100-950 (mm) |

| Motor : 110 K.w , 900 Rpm |

Con Crusher 4 * 36

- Used As Primary And/or Secondary Crusher In Mines

- High Ability To Crush Hard Rocks

- Suitable For Producing

- The Large Input Opening

- Very Strong And High Resistance Structure During Crushing Operation

- Friction Parts Made Of Mn Steel

- Easy Carrying &Installation Caused By Low Weight

| Specifications: |

| Model : C 4 * 36 |

| Dimension(m) : 2 * 3 * 3.7 |

| Weight(kg) : 10,000 |

| Capacity (t/h): 100 |

| Max-Feed(mm) : 80 * 80 * 95 |

| Motor : 125 Hp , 90 K.w , 1400 Rpm |

Con Crusher 5 * 36

- Used As Primary And/or Secondary Crusher In Mines

- High Ability To Crush Hard Rocks

- Suitable For Producing

- The Large Input Opening

- Very Strong And High Resistance Structure During Crushing Operation

- Friction Parts Made Of Mn Steel

- Easy Carrying &Installation Caused By Low Weight

| Specifications: |

| Model : C 5 * 36 |

| Dimension(m) : 2 * 3 * 3.7 |

| Weight(kg) : 10,500 |

| Capacity (t/h): 115 |

| Max-Feed(mm) : 100 * 100 * 125 (mm) |

| Motor : 125 Hp , 90 K.w , 1400 Rpm |

Con Crusher 8 * 36

- Used As Primary And/or Secondary Crusher In Mines

- High Ability To Crush Hard Rocks

- Suitable For Producing

- The Large Input Opening

- Very Strong And High Resistance Structure During Crushing Operation

- Friction Parts Made Of Mn Steel

- Easy Carrying &Installation Caused By Low Weight

| Specifications: |

| Model : C 8 * 36 |

| Dimension(m) : 2 * 3 * 3.7 |

| Weight(kg) : 10,700 |

| Capacity(t/h) : 170 |

| Max-Feed (mm): 190 * 190 * 210 (mm) |

| Motor : 125 Hp , 90 K.w , 1400 Rpm |

Vibrating Screen 3*

- Tenacious &High Resistance Structure

- Body Made Of Plates Without Suture Weld

- Shafts Made Of Alloy Steel

- Vibration Amplitude Adjustment

- Perfect Lubricant System & Use Of Caulk Tools

- Use Of Double Spherical Roller Bearing For Revolving Movement Quick &Easy Installation and Replacement

| Specifications: |

| Model : 6 * 2 |

| Dimension (m): L 7.06 * W 3.40 * H 4.79 |

| Weight(kg) : 5,350 |

| Capacity(t/h) : 180-300 t/h |

| Decks: 3 |

| Motor : 20 Hp , 15 K.w , 900 Rpm |

Horizontal Feeder

- Suitable For Mountain Mines With Large Stones

- Tenacious &High Resistance Structure

- Includes Grizzly System In Front Of The Structure

- Includes Very Great Storage With 60 Tons Capacity

- Using Double Spherical Roller Bearing For Revolving Movement

- Shafts Made Of Alloy Steel

- Movement Amplitude Adjustment In Locomotive

- Use Of Anti-friction Plates For The Body And The Bottom

- Perfect Lubricant System &Caulk Tools

| Specifications: |

| Model : HF 4.8 * 1.2 |

| Dimension(m) : 3100 * 1700 * 806 |

| Weight(kg) : 24,000 |

| Capacity (t/h): 550 |

| Motor : 37 K.W , 900 Rpm |

Conveyor Belt(230m)

- Includes frame contains spar

- Various length to be m used in any plant

- Includes SN 516 bearings and K 61222-2T roller bearings

- Easily vise or replaceable rollicks

- Contains Bolt & Nut junctions in parts such as conveyor structure engine prop,gear box prop , rollick prop ,preservatives,…

- Belt layout according to the map :

-

1- 100 * 18 2- 100 * 18 3- 100 * 16 4- 80 * 22 5- 80 * 20 6- 80 * 20 7- 80 * 20 -

8 – 80 * 16 9 – 80 * 18 10- 80 * 16 11- 80 * 18 12- 80 * 16 13- 80 * 18 14- 80 * 18

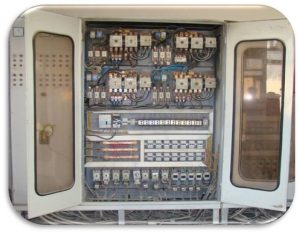

Control Cabin

- Power distributer frame and piano shape control with electrostatic color, Siemens and in bolt and nut shape.

- Using of bimetals with appropriate range for protecting contactors against extra power

- Hydro-con controller system with the capability of sensitive and accurate function from Techno-Electric Engineering

- Using of start chaste and Taiwan step

Cable Layout

| 1- 1800 m : 3 * 6 |

| 2- 250 m : 3 * 35 |

| 3- 200 m : 16*1.5 |

| 4- 100m : 2 *1.5 |

| 5- 25 m : 30*135+120 |